Advanced Filters

Category

Manufacturer

Year

APT isn’t just a reseller. We’ll consult with your team to make sure you find the perfect machine. We use our in-house accredited appraisal team, making sure you get the best value from your used equipment and machinery. We transport machines all across the globe, from South Plainfield, NJ to Hyderabad, India. And once at your facility, we install our machines to run perfectly, train your team to use your new-to-you machine efficiently, and offer service and maintenance to keep your production floor running.

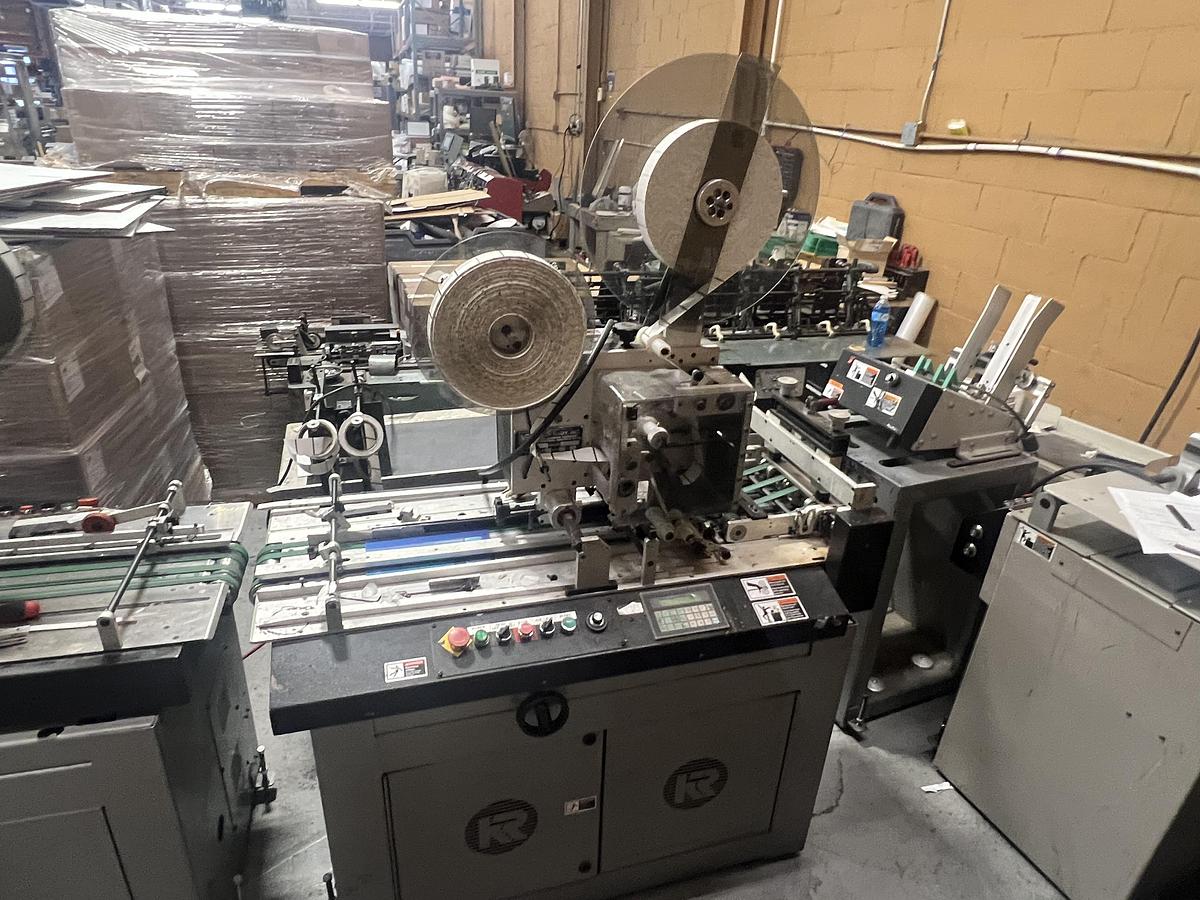

“Boost mailing productivity with the Kirk-Rudy 535 Tabber "

Used 2013 Kirk Rudy 535 Tabber Kirk-Rudy 535 Tabber – High-Speed Tabbing Machine for Mailing & Fulfillment

- Manufacturer

- Kirk Rudy

- Model

- 535 Tabber

- Stock Number

- 00056

- Year

- 2013

Complete Mailing & Distribution System – High-Speed Addressing, Labeling & Fulfillment

Used 2013 Kirk Rudy Complete Mailing & Distribution System – High-Speed Addressing, Labeling & Fulfillment

- Manufacturer

- Kirk Rudy

- Category

- Mailing Equipment

- Stock Number

- 00055

- Year

- 2013

Used 2014 Komori GL640-C 6-Color Offset Press | For Sale

Used 2014 Komori GL640-C 6-Color Offset Press | For Sale

- Manufacturer

- Komori

- Model

- GL 640+c

- Stock Number

- 00054

- Year

- 2014

Featured

USED 2023 FUJI J PRESS 750 HS PRODUCTION INK JET PRESS

- Manufacturer

- FUJI

- Model

- J PRESS 750 HS PRODUCTION INK JET PRESS

- Stock Number

- 00053

- Year

- 2023

Featured

Used 2007 Komori LS-840P+ANILOX COATER

- Manufacturer

- Komori

- Model

- LS-840P+ANILOX COATER

- Stock Number

- 00036

- Year

- 2007

Featured

2022 Heidelberg CX104-6+LX Hybrid UV

- Manufacturer

- Heidelberg

- Model

- CX104-6+LX Hybrid UV

- Stock Number

- 00048

- Year

- 2022

Featured

2019 KBA Rapida 105-5+L FAPC ALV2 CX - Hybrid UV & LED-UV

- Manufacturer

- KBA

- Model

- Rapida 105-5+L FAPC ALV2 CX - Hybrid UV & LED-UV

- Stock Number

- 00043

- Year

- 2019

Featured

2020 KBA 106X-RDC-8-SW5+L FAPCX ALV2

- Manufacturer

- KBA

- Model

- 106X-RDC-8-SW5+L FAPCX ALV2

- Stock Number

- 00028

- Year

- 2020

Featured

2020 KBA 106-6+L CX FAPC ALV2 20K

- Manufacturer

- KBA

- Model

- 106-6+L CX FAPC ALV2 20K

- Stock Number

- 00017

- Year

- 2020

Featured

2018 Heidelberg XL106-7+LX3 Hybrid UV

- Manufacturer

- Heidelberg

- Model

- XL106-7+LX3 Hybrid UV

- Stock Number

- 00016

- Year

- 2018

Featured

PMC PMC Model J Die Cutting Machine S/N J-850

- Manufacturer

- PMC

- Model

- PMC Model J Die Cutting Machine S/N J-850

- Stock Number

- 00011

Featured

PMC PMC Model 200 Series 9 x 12 Die Cutting Machine S/N 1356

- Manufacturer

- PMC

- Model

- PMC Model 200 Series 9 x 12 Die Cutting Machine S/N 1356

- Stock Number

- 00010